In Woven sacks industry the most common observation is that ends of “Cheese Pipes” made of MS have sharp edges, which cut through base of plastic crate thus making holes in the crate which eventually breaks the crate. To solve these problems “CHAIRish” Crates are designed.

Most widely used size for various industries :-

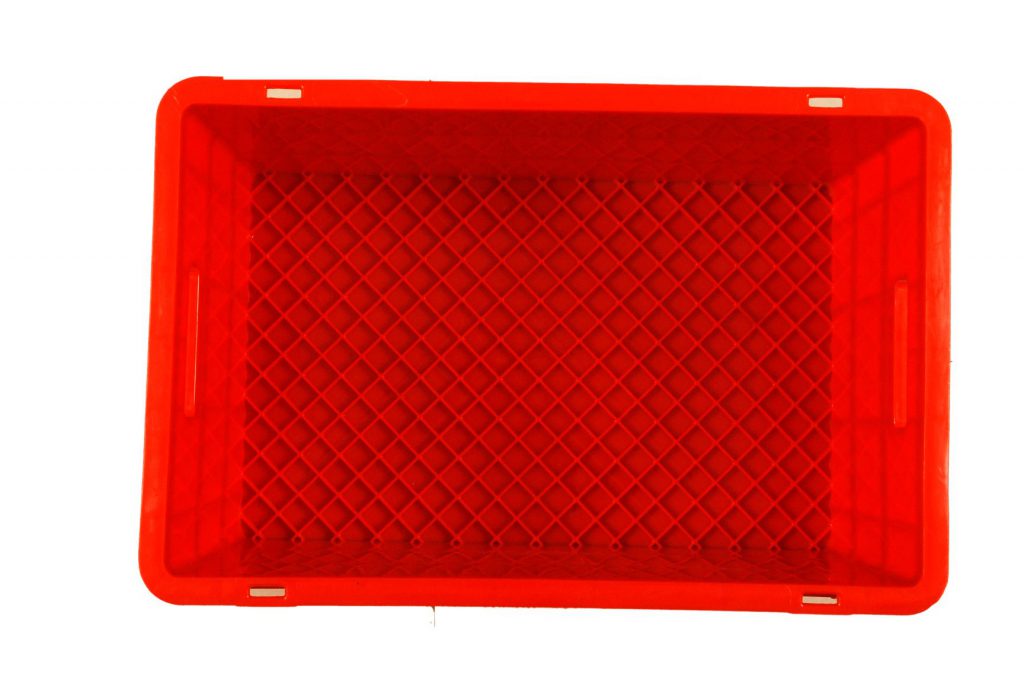

Outer Dimension:500 mm (L) x 332 mm (W) x 250 mm (H) Inner Dimension:465 mm (L) x 290 mm (W) x 240 mm (H)

Salient Features Of Crates For PP/HDPE Raffia (Woven Bags)

Crate is made of virgin HDPE. Base of the crate is specially designed for higher load bearing capacity and continuous ruggedness on the factory floor.Thickness of crate base is 19 mm (7 mm ribs on each side + 5 mm base)instead of 7 mm in regular crates( 4 mm base + 3 mm outside ribs) . The base thickness is 2.5 times more compared to the standard crates which will certainly increase the life of the crates.

In order to strengthen the crate our design has checkered ribs of 7 mm height at 25.4 mm distance between two consecutive ribs so that the cheese pipes (having OD of 32 mm) does not touch the crate base directly. Hence specially designed checkered ribs act as protection to the base adding longer life to the crates.

It is observed that the crates are being dragged around on the factory floor, so the base gets worn out soon which breaks the crate. Our specially designed ribs on the outer part of the base delays wearing out of the base and makes our crates much more stronger the than standard crates.

Additional Reinforcements on the side walls and corners of the crates gives more rigidity and strength to the crates, which means more number of crates can be stacked than usual.

Spacing of the square ribs on the side walls is specially designed to handle crates with heavy loads in a better way.